Close search

With the rapid development of the refractory industry, the requirements for mixing technology are increasing day by day. At present, the formulation of refractory materials is often very complex, and the ratio of different ingredients has a direct impact on the performance of the product. For example, the proportion of raw materials such as silicon carbide, fireclay and bauxite needs to be strictly controlled.

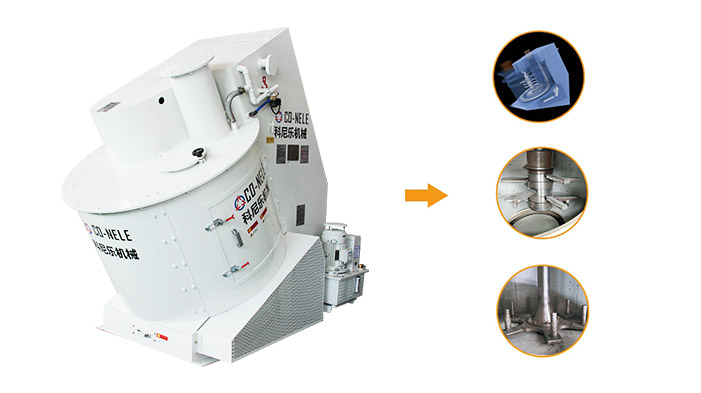

The refractory industry is usually in a high temperature, high pressure, high dust environment, the mixer needs to have high efficiency and stability to ensure the continuous and stable operation of the production line. The intensive mixer can complete the mixing process quickly and with high quality, and can adapt to the production needs of different batches to ensure the efficient operation of the production line.

We will contact you within 24 hours.