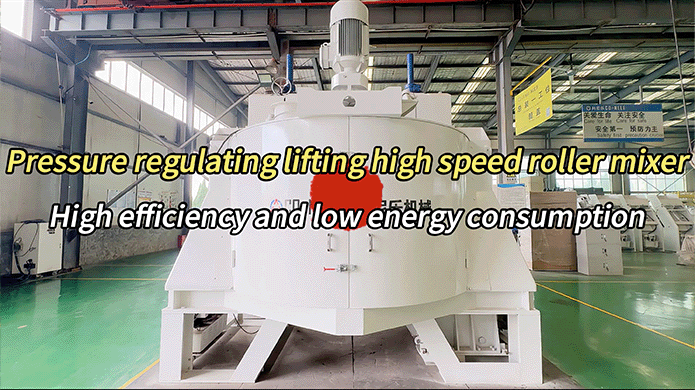

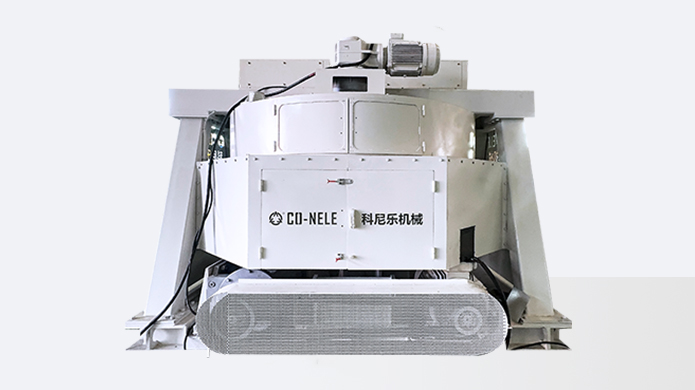

The muller mixer is a new mixing plant designed by CONELE for the refractory(stemming)and ceramic industries.The pressure-adjustable lifting high-speed grinding wheel mixer is an innovative design of our company based on the characteristics of the ceramic and refractory industries.It is based on the advanced and rigorous technical concepts of Europe.The grinding wheel is designed as a lifting structure,which can adjust the pressure and has the function of pressure-maintaining overflow,making the material rolling more thorough and ideal,making the mixed material denser,with fewer pores and better performance.

Advantages of muller mixer

The differential mode of main stirring combined with high-speed stirring is adopted

The material is mixed evenly and there is no dead angle

The mixed material has high density and few pores

The double roller has adjustable pressure and pressurization function

High degree of automation

Novel and beautiful appearance design

Muller mixer uses thickened barrel liner and more wear-resistant materials to improve wear resistance,which can reduce the failure rate,reduce maintenance costs and extend the service life of the equipment in use.

Type Of Muller Mixer

| Type | Mixing capacity(kg) | Main planet/blade(nr) | Auxiliary mixing(nr) | Dimension(mm) |

|---|---|---|---|---|

| CDL19 | 500-1000 | 1/2 | 1 | 2700×2200×2530 |

| CDL27 | 1500-2000 | 1/2 | 1 | 3740×3182×3500 |

Why Choose Our Muller Mixer

Reduced Mixing Duration

Improved Homogeneity

Long Service Life

Uniform Mixing of All Refractory Raw Material