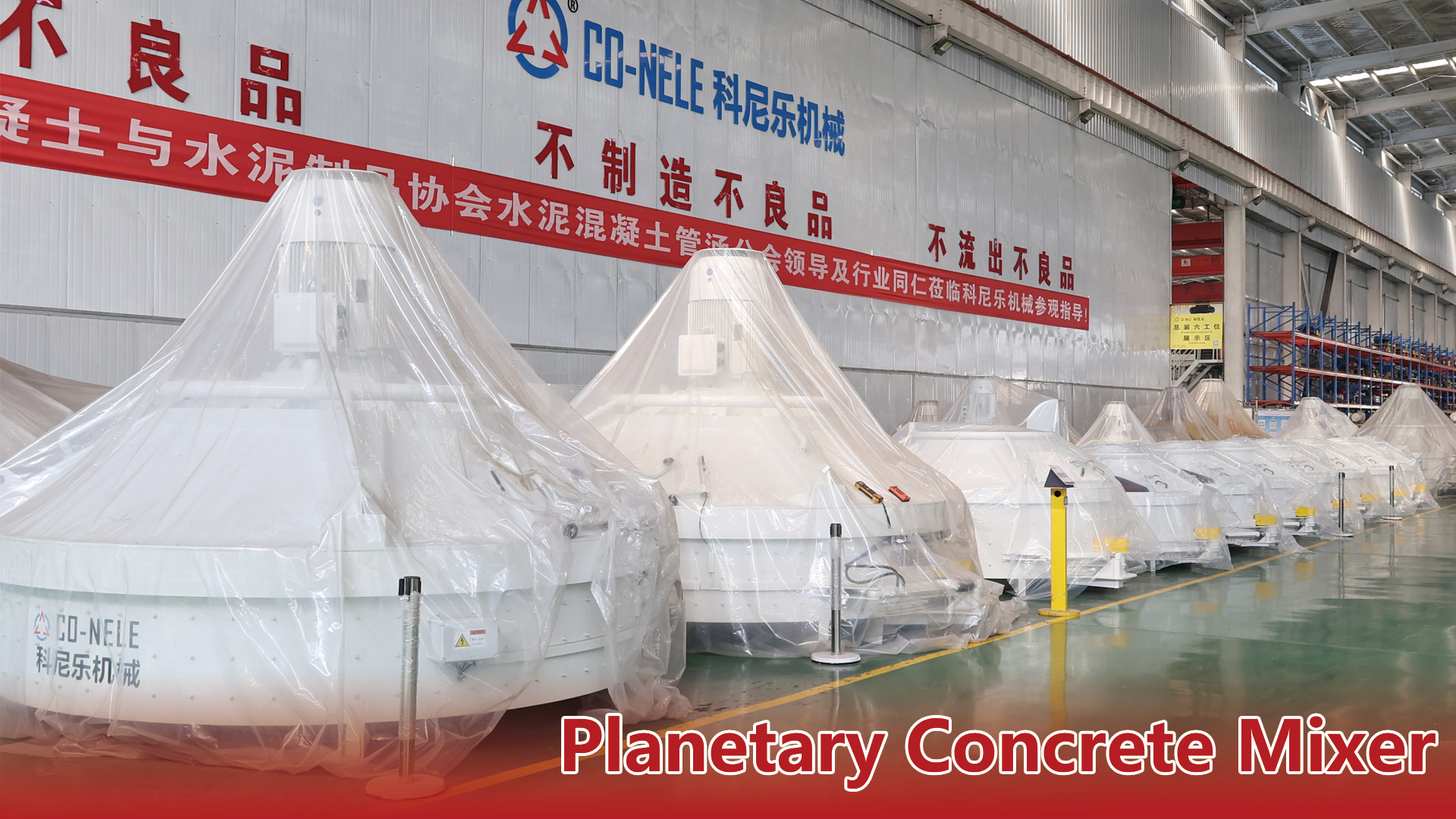

Planetary Concrete Mixer

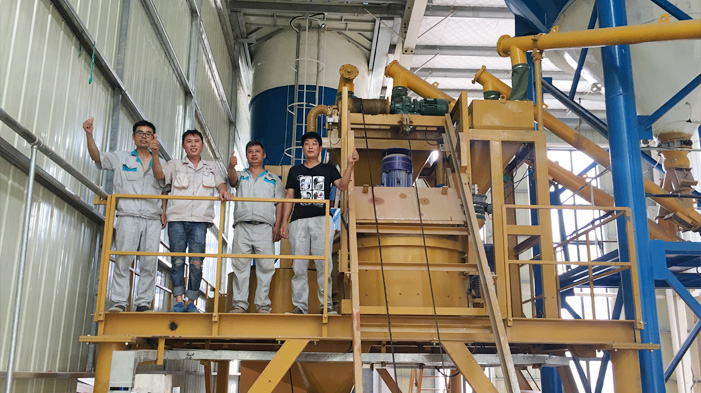

CO-NELE planetary concrete mixer has independent intellectual property rights, higher mixing efficiency and high mixing quality.

CO-NELE company become the most comprehensive professional planetary concrete mixer and concrete batching plant manufacture supplier in China.

Features:

1. CMP series vertical axis planetary concrete mixer is suitable for precast concrete (PC components, pipe piles, sleepers, subway segments, floor tiles, ladders, etc.), light industry, heavy chemical industry (glass, ceramics), slag, coal ash and other raw materials. mixing.

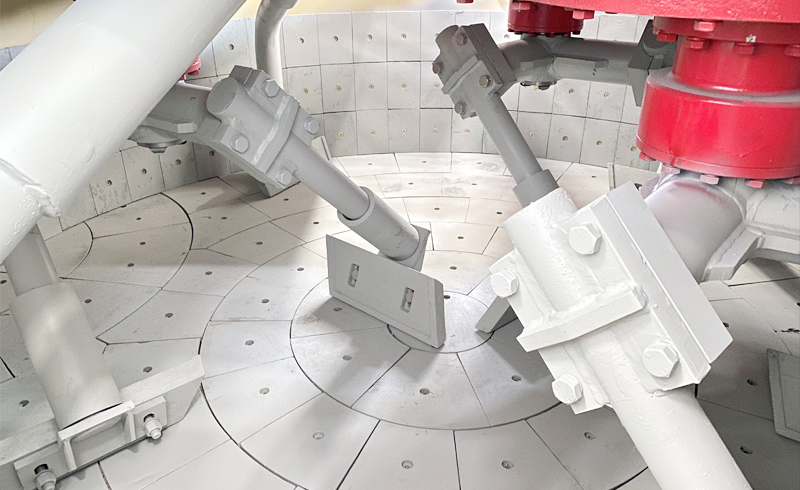

2. Reasonable mixing speed and complex motion trajectory design make the mixing of various materials more intense, more uniform and higher productivity.

3. The specially designed stirring device makes the stirring speed faster and the mixing more uniform; the mixing blade is more resistant to wear;

4. Flexible coupling and hydraulic coupler (optional) can effectively protect the transmission system from the impact of overload;

5, planetary gearbox, with low noise, large torque, strong durability, low maintenance costs.

6. There is no direct contact between the various mixing materials and the output part of the transmission, and there is no problem of slurry leakage in the twin-shaft mixer.

7, hydraulic discharge. The hydraulic unloading design has a special hydraulic pumping station, which can meet the configuration of three discharge doors, and has a manual unloading function. In an emergency, the discharge door can be manually opened.

8. Reasonably designed discharge door has a more reliable sealing structure to avoid leakage;

9. Maintenance door design, more convenient maintenance and cleaning; special sealing device, more environmentally friendly, and high reliability and high sensitivity safety switch.

10. There are high pressure cleaning devices and humidity testers (optional);