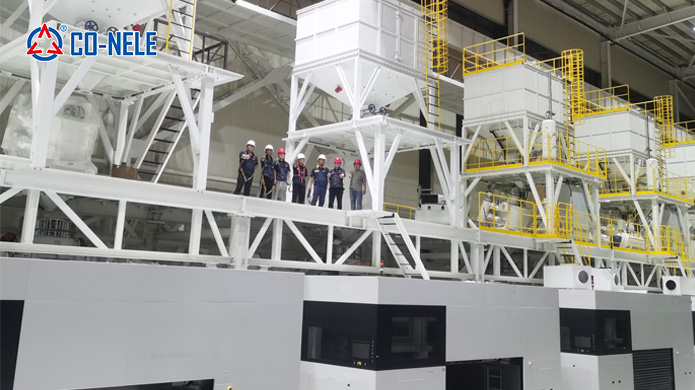

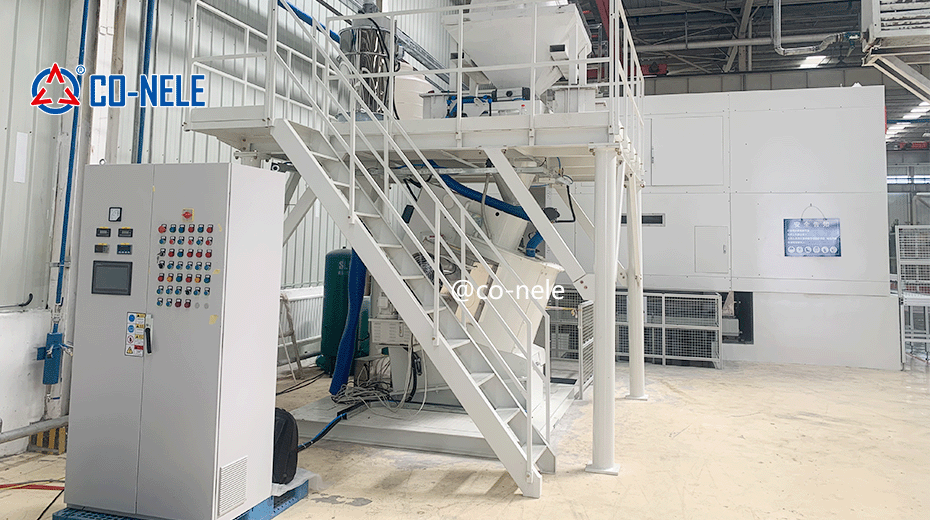

Efficient, precise and intelligent foundry sand mold preparation solution

CO-NELE's unique sand mixing process guarantees stable/reproducible sand quality, unaffected by other factors in the process, providing a perfect 3D printing sand mixing system solution.

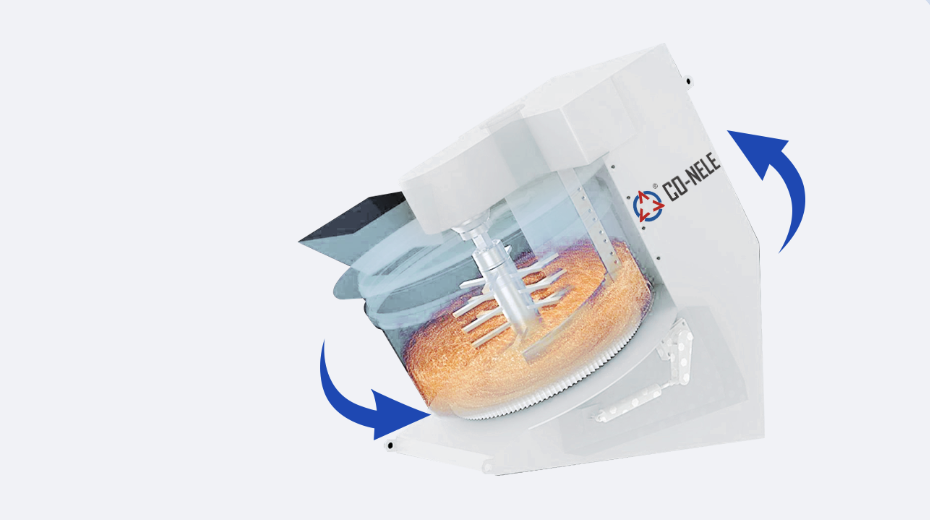

Sand and extensive expertise in pre-mixing, homogenization, moisture content testing and correction, final mixing and unloading. When the unloading door is opened, the composite sand is ready for use - with optimal flow characteristics, uniformity and agglomeration-free consistency.

Foundry sand mixer parameters

Efficient, precise and intelligent foundry sand mold preparation solution

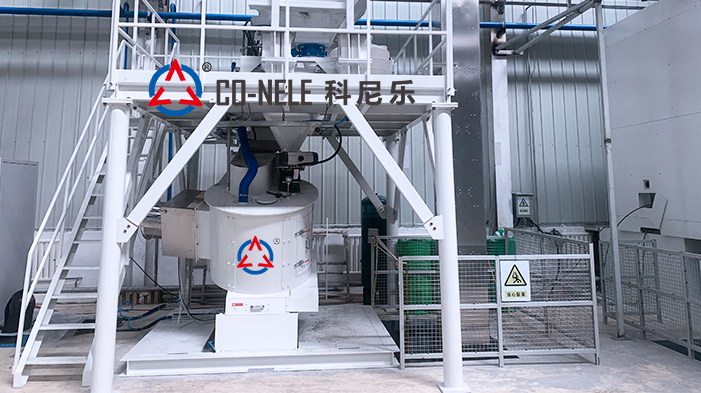

CO-NELE's unique sand mixing process guarantees stable/reproducible sand quality, unaffected by other factors in the process, providing a perfect 3D printing sand mixing system solution.Sand and extensive expertise in pre-mixing, homogenization, moisture content testing and correction, final mixing and unloading. When the unloading door is opened, the composite sand is ready for use - with optimal flow characteristics, uniformity and agglomeration-free consistency.

Co-Nele's 3D printing Intensive foundry sand mixer can achieve a sand mixing capacity of 0.3t/h-60t/h.

20 batches/hour.

| Foundry Sand Mixer | Hourly Production Capacity:T/H | Mixing Quantity:Kg/batch | Production Capacity:m³/h | Batch/Liter | Discharging |

| CR05 | 0.6 | 30-40 | 0.5 | 25 | Hydraulic center discharge |

| CR08 | 1.2 | 60-80 | 1 | 50 | Hydraulic center discharge |

| CR09 | 2.4 | 120-140 | 2 | 100 | Hydraulic center discharge |

| CRV09 | 3.6 | 180-200 | 3 | 150 | Hydraulic center discharge |

| CR11 | 6 | 300-350 | 5 | 250 | Hydraulic center discharge |

| CR15M | 8.4 | 420-450 | 7 | 350 | Hydraulic center discharge |

| CR15 | 12 | 600-650 | 10 | 500 | Hydraulic center discharge |

| CRV15 | 14.4 | 720-750 | 12 | 600 | Hydraulic center discharge |