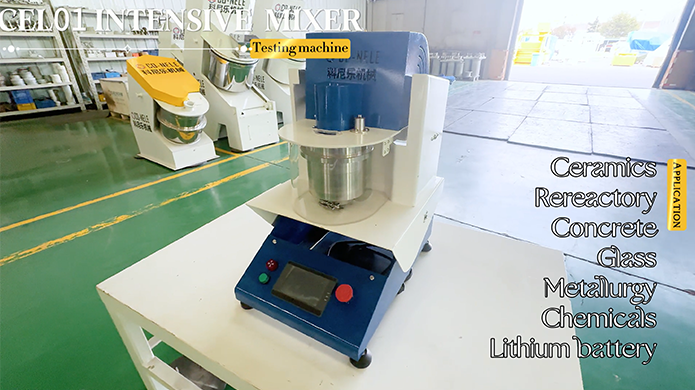

CEL01 Intensive Laboratory Mixer

Adjustable tilt angle 0°, 10°, 20° and 30°

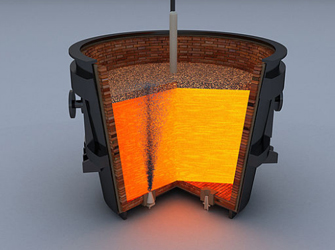

The mixing cylinder is configured according to user needs, the internal rotor and side hanging plate are available in a variety of optional materials, the internal lining can be customized, and various wear protections are provided according to requirements.

Laboratory 1L small mixer functions optional: vacuum, heating, cooling functions.

CEL01 Intensive Laboratory Mixer Advanced Control Technology

The control system is advanced and flexible, with an optional touch screen, intuitive operation, and infinitely adjustable tool speed in the direction of rotation. Users can set and adjust the rotation speed (mixing disk), power (mixing tool), temperature, time, etc. through a graphical interface.

Type Of Laboratory Intensive Mixer

| Type | Out capacity(L) | Out weight(Kg) | Mxing Power(Kw) | Main planet(nr) |

|---|---|---|---|---|

| CEL01 | 1 | 1.2 | 0.4 | 1 |

| CEL5 | 5 | 6 | 2.2 | 1 |

| CR02 | 5 | 6 | 2.2 | 1 |

| CR04 | 10 | 12 | 4 | 1 |

| CEL10 | 10 | 12 | 4 | 1 |

| CR05 | 25 | 30 | 7.5 | 1 |

| CR08 | 50 | 60 | 11 | 1 |