Offshore Wind Power Grout Plant

The offshore grouting mixing plant is an automated production system designed specifically for offshore wind power monopile,pipe rack and other foundation structure grouting construction.Its core function is to efficiently mix high-precision grouting materials to ensure the long-term stability and fatigue resistance of offshore wind power foundations.

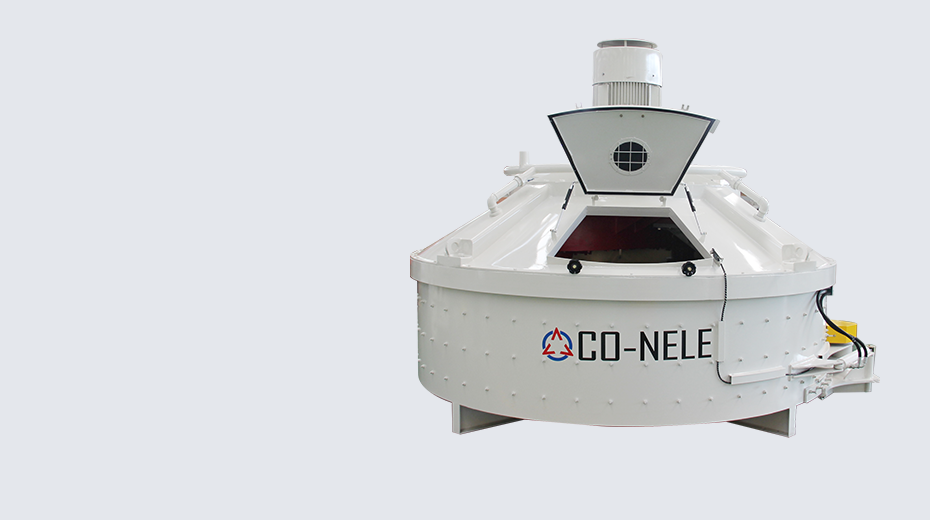

Offshore grouting mixing system:Mix the grouting materials evenly.It is recommended to use a planetary mixer(uniformity 98%).

Batching system:accurate metering of raw materials(cement,sand,additives),weighing accuracy±0.5%

Pumping system:high pressure delivery to the construction site

Control system

Why Planetary Mixers are Ideal for Offshore Grouting

Advantages over traditional mixers:✅Excellent mixing quality-elimination of dead zones(critical for epoxy grouting)

✅Corrosion resistance

✅Energy saving-15-20%lower power consumption compared to twin-shaft mixers

✅Low maintenance cost-wear-resistant alloy blades(life 10,000+hours)

Key selection parameters

Capacity:Select according to the scale of the wind farm(for example:a single pile of an 8MW wind turbine requires about 50m³of grouting material,and a 2m³planetary intermittent mixer is recommended).

Typical process flow of offshore grouting mixing plant

Raw material pretreatment:sand and gravel drying(humidity≤0.5%),cement screening(particle size≤80μm).Precise measurement:weighing sensor error≤±0.5%(in compliance with ISO9001 standards).

High-efficiency mixing:vertical planetary mixer(speed 20-60rpm,mixing time 3-5 minutes).

Quality inspection:fluidity(fluidity≥35cm),compressive strength(28 days≥80MPa).

Pumping:transported to the foundation interface by a high-pressure pump(pressure≥3bar).