What Our Clients Say

As a lithium battery material manufacturer, mixing uniformity and consistency are directly related to battery performance and safety. The CO-NELE CEL01 Intensive Lab Mixer has significantly improved the tap density and batch consistency of our products. In particular, its unique granulation function enables precise control of particle size distribution, which is crucial for our subsequent sintering process. - From Canada

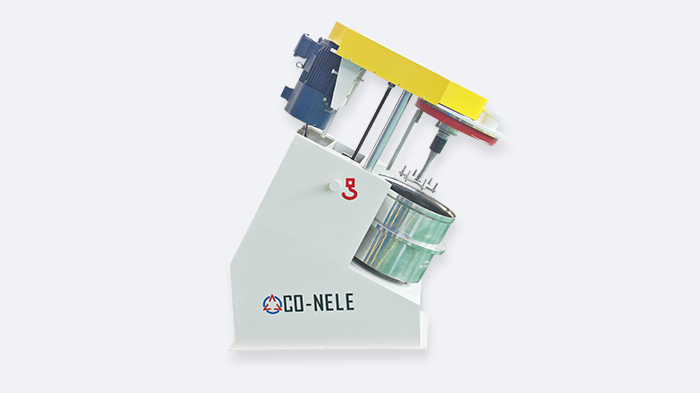

We handle a variety of metal powders with very different specific gravities, and traditional mixers are prone to stratification and segregation. Since the introduction of the CO-NELE CR02 Intensive Lab Mixer, all problems have been solved. - From North America

High production volumes and continuous operation are our primary requirements for equipment. The CO-NELE continuous intensive mixer's exceptional production capacity meets our needs. Its three-dimensional mixing technology rapidly and evenly blends various trace elements with basic fertilizers, resulting in granulated products with high strength and excellent roundness. —From Brazil

Customer: A European automotive brake pad manufacturer. CO-NELE CR15 Intensive mixer provides excellent dispersion of fiber materials, ensuring consistent friction coefficients and physical properties for every batch. The equipment is also easy to clean, a significant advantage for our R&D work, which frequently involves changing formulations.

Application: Mixing and granulating materials such as bentonite and bauxite.The CO-NELE Granulator machine is used for mixing and granulating proppant coatings. It ensures that each ceramsite particle is evenly coated, significantly improving our product yield and performance——Middle Eastern proppant manufacturer

We are dedicated to producing the most complex building facade components, placing extremely high demands on the flowability and fiber dispersion uniformity of UHPC. The CO-NELE planetary mixer for UHPC completely solved our long-standing problems of fiber agglomeration and material segregation. —Germany's high-end precast component manufacturer

CO-NELE's mobile UHPC batching plant demonstrates remarkable efficiency and stability. It rapidly produces ultra-high-performance repair materials on-site, with exceptional compressive strength and durability far exceeding state standards. - North American bridge repair contractor

Our UHPC staircases are known for their 'floating' feel and minimalist design. This poses dual challenges to the material's weight and strength. Since introducing CO-NEEL's mixing system, we've successfully reduced product thickness by 20% while still meeting strength standards. - Australian precast staircase manufacturer