New Type Fertilizer Granulator

Transforms raw fertilizers into small, uniform particles called granules through the process of fertilizer granulation. These granules, which are more convenient to handle and apply to crops, are easier to spread evenly and do not clump together like raw fertilizers.

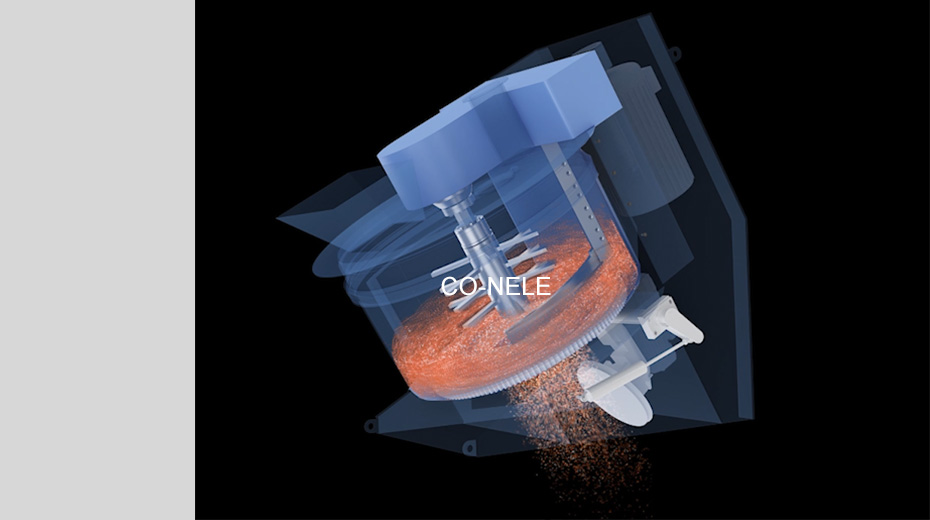

New type fertilizer granulator is a process equipment used in fertilizer granulation. enables fine mixing, granulation and coating in a single machine,It is widely used in the organic and mineral sectors.

✅FertilizerNPK, organic, organo-mineral etc.

✅Agriculture

Animal feed, herbicides, pesticides etc.

✅Biomass

Manure, compost, sludge etc.

Fertilizer plant granulation production line

In fertilizer granulation plants, The raw materials to be fed into the system can be powder or coarser materials. In the case of coarser materials, they are usually ground by means of a crusher at the inlet. organic sources usually arrive at the facility with high humidity. it is difficult to break the moist material. the organic material is first dried and then crushed.

The organic mineral fertilizer granulation production line is an automated system that integrates multiple equipment. CO-NELE is specially designed to scientifically proportion, mix, granulate, coat, dry, cool, screen, coat (optional) and package organic materials (such as livestock and poultry manure, straw, kitchen waste, humic acid, sludge, etc.) with inorganic mineral nutrients (such as nitrogen, phosphorus, potassium, trace elements, etc.), and finally produce a complete set of equipment for granular organic mineral compound fertilizers. Main processes and key equipment for complete sets of equipment for organic mineral compound fertilizers:

✅Pre-granulation process (Raw material process——Bachting syastem)

✅Mixing section✅Granulation process (core)

✅Post-granulation processes(Coating——Drying——Cooling——Packaging)