Close search

The composition of the tap hole clay mainly includes refractory aggregate and binder, refractory aggregate is usually composed of corundum, mullite, coke and other refractory raw materials and modified materials such as coke, mica, binder can be water or organic materials such as tar pitch and phenolic resin. In addition, the production process includes raw material premixing, adding binder, extrusion molding, etc.

Tap hole clay is the refractory material used to seal the iron outlet in the process of blast furnace smelting, and it is the key material to ensure the smooth operation of blast furnace. With the rapid development of iron and steel industry, blast furnaces are developing to large-scale, long-life and intensive smelting, and the performance requirements of tap hole clay are getting higher and higher. Modern tap hole clay requires good processability (filling and opening), permeability, sintering, compatibility between old and new mud, corrosion resistance and erosion resistance.

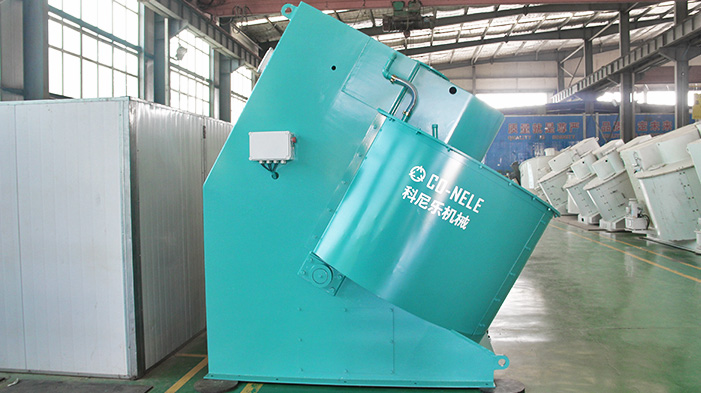

The CONELE intensive mixer is specially used for the mixing of refractory materials and other raw materials. The barrel of the intensive mixer is rotated clockwise, the high-speed axis is rotated counterclockwise, and the raw materials are crushed and mixed by the high-speed rotating axis. The inner cylinder has a scraper, so that the surrounding material into the center of the powerful mixer for crushing. Therefore, the intensive mixer has the characteristics of high efficiency, no dead angle and even mixing.

Tap hole clay intensive mixer adopts PLC automatic control, smooth running, easy operation, which is the ideal mixing equipment.

We will contact you within 24 hours.