Close search

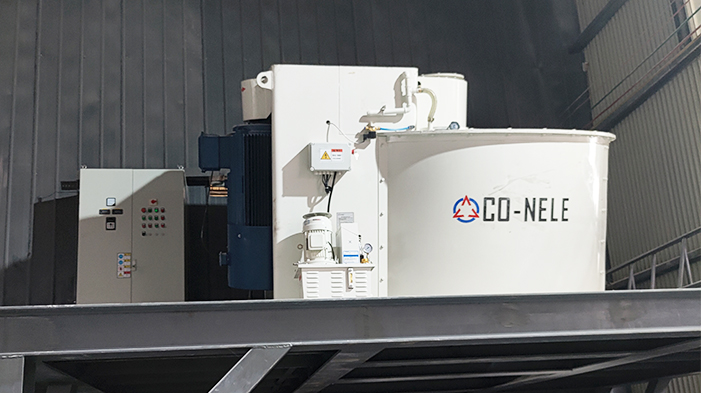

Counter current intensive mixer for refractory can be designed according to the principles of countercurrent or lateral flow. It can achieve rapid and uniform mixing of materials according to the properties of refractory materials, with high mixing efficiency, uniform mixing, and environmental protection without pollution.

In the refractory industry, the counter current intensive mixer is mainly used for the mixing, blending, granulation and special preparation of various refractory raw materials. It is mainly used for:

· Aluminum, magnesium refractory brick

· Light firebrick, foam material

· Filling materials, spraying materials and spraying materials

· Refractory mud and sealing material

· Castable

· Prefabricated parts

· Continuous casting of three large parts

The advantages brought to production:

· Robust design ensures excellent service life and efficient utilization

· Wear parts are very accessible, so easy to replace

· The seal ring is not in direct contact with the mixture

· Compared to other mixing systems, the yield and mixing strength of Cornelle's batch-produced power mixers can be adjusted independently:

· The speed of the mixing tool can be adjusted from fast to slow

· The energy input of the mixture can be set for the mixed product

· Can achieve staggered mixing process, such as: slow speed - fast - slow speed

We will contact you within 24 hours.