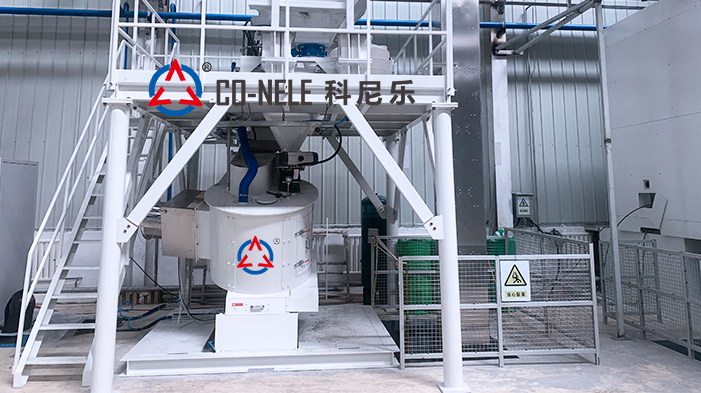

Foundry 3D Printing Sand Mixer & CONELE Intensive MixerThe 3D printing sand mixer is a cutting-edge high-tech device designed for the foundry industry, combining advanced 3D printing technology with traditional sand mixing processes. It enables rapid and precise preparation of complex sand molds (sand cores or sand molds). Whether for small-batch customization or large-scale production, our 3D printing sand mixer delivers efficient and reliable solutions, driving the foundry industry toward an intelligent and digitalized future.CO-NELE 3D Printing High-Intensity Sand MixerThe CO-NELE 3D printing high-intensity sand mixer offers a mixing capacity ranging from 0.3 t/h to 60 t/h.Unique Advantages of CO-NELE TechnologyCO-NELE's exclusive sand mixing process ensures stable, reproducible sand quality, unaffected by external factors in the production workflow, delivering a perfect 3D printing sand mixing system solution.Our expertise spans pre-mixing, homogenization, moisture content testing and adjustment, final mixing, and discharge. When the discharge gate opens, the composite sand is ready for use—optimized for flow characteristics, uniformity, and lump-free consistency.Core Features of the 3D Printing High-Intensity Sand MixerHigh-Efficiency Sand Mixing SystemRapid & Uniform Mixing: The tilted design enhances the movement of sand and binders during mixing, improving sand mold strength and consistency while ensuring fast and uniform blending.High Speed & Productivity: Significantly reduces production cycles with accelerated mixing speeds.Flexible AdjustabilityAdjustable Rotation Speed: Optimize mixing effects by adjusting speed based on sand properties.Tilt Angle Control: Customize mixing time and intensity by adjusting the drum tilt angle to meet diverse process requirements.Rational Structural DesignCompact Footprint: Space-efficient design ideal for limited workspace environments.Durability: Built with wear-resistant materials to extend service life and reduce maintenance costs.User-Friendly OperationIntegrated PLC Control System: Enables fully automated processes from mixing to printing, minimizing manual intervention.Smart Features: One-touch start, auto-cleaning, and fault diagnosis for simplicity and convenience.Energy Efficiency & Eco-FriendlinessLow Energy Consumption: High-efficiency mixing reduces energy costs.Closed Design: Sealed structure minimizes dust and noise emissions, improving workplace safety and comfort.Versatility & CompatibilityHandles multiple sand types (e.g., quartz sand, ceramic sand) and binders (e.g., furan resin, sodium silicate), adapting to diverse casting material requirements.

Tags:

Foundry 3D Printing Sand Mixer

Tilting High-intensity Sand Mixer

Sand Mixer Manufacturer

Intensive mixer

Back To The List