Close search

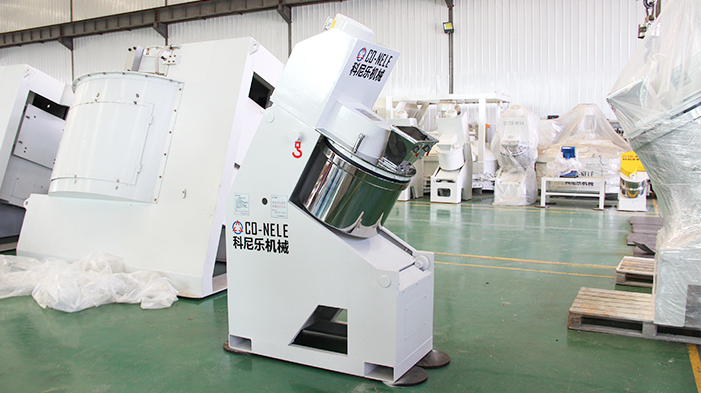

Alumina ceramic mixing granulator equipment features:

Efficient mixing granulation: The mixing platter/mixing knife is a key component of the granulation device, which produces strong three-dimensional turbulence through high-speed rotation, acts on the material, causes physical and chemical changes between the material particles, and gradually forms the required granular products. It can achieve full contact and uniform mixing between alumina particles in a short time.

Precise control: Intensive mixer equipped with advanced control system, such as PLC programmable controller, touch screen operation interface, can accurately control the mixing time, temperature, humidity and other key parameters to ensure the consistency and stability of the mixing process.

Corrosion resistance and wear resistance: Due to the high hardness and easy caking characteristics of alumina materials, mixed granulators usually use wear-resistant and corrosion-resistant materials to manufacture mixing parts and parts that contact materials, such as stainless steel, high-alloy steel, etc., to ensure the long-term stable operation of the equipment.

Alumina ceramic mixing granulator is widely used in ceramics, refractory materials, metallurgy, environmental protection, glass, building materials and other industries. Through the granulation process, the fluidity, loose density and surface reactivity of alumina powder can be improved, and the performance and production efficiency of the product can be improved.

We will contact you within 24 hours.