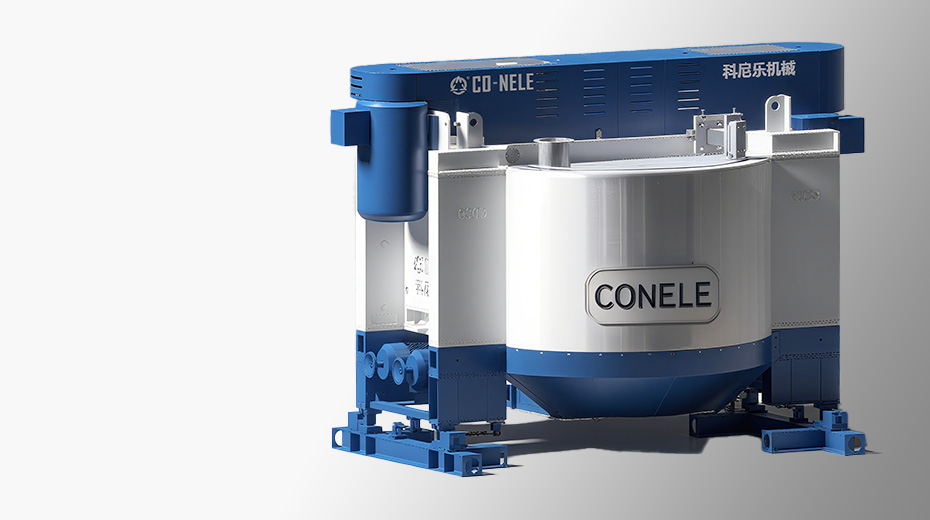

Co-Nele Continuous Intensive Mixer is designed to help you break through these limitations!

Continuous Intensive Mixers Core Advantages

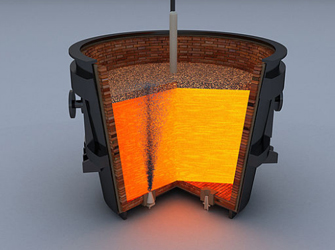

Superior Production Capacity: Offering a wide range of processing capacity, from 20 tons/hour to an industry-leading 1,400 tons/hour, it perfectly meets the needs of medium-sized production lines to ultra-large industrial projects (such as those in the mining, building materials, and metallurgical sintering and pelletizing industries).

Unparalleled Uniformity: Utilizing a unique shear and convection hybrid mixing principle, it ensures near-perfect distribution of even trace amounts of additives or moisture in a very short time, significantly improving final product quality.

Continuous Production, Ultimate Efficiency: Say goodbye to waiting times during intermittent production. Achieve true 24/7 continuous feeding and discharging, significantly improving overall production efficiency and reducing specific energy consumption and operating costs.

Rugged, Durable, and Low-Maintenance: Designed to handle highly abrasive and corrosive raw materials. Core components are made of wear-resistant alloys and specially coated to ensure long life and stable operation in harsh operating conditions. The Co-Nele continuous intensive mixer combines mixing, granulation, and coating in a single unit. The Co-Nele intensive mixer separates the transport of the mix from the actual mixing process. This allows variable speed operation from slow to fast, allowing for controlled mixing intensity that can be easily adjusted to the application and product being mixed. Furthermore, mixing in a "mix" cycle, such as slow-fast-slow, is also possible.

Continuous Intensive Mixers Technical Parameters

| Type | Mixing Capacity | Continuous productivity | Main rotor power |

| CR15L | 500-1000 Liters | 20-70t/h | 55Kw |

| CR19L | 1000-1500 Liters | 30-100t/h | 75Kw |

| CR20L | 1500-2000 liters | 40-130t/h | 90Kw |

| CR24L | 2000-3000 liters | 50-200t/h | 110Kw |

| CD29L | 4000-6000 liters | 150-450t/h | 110Kw+132Kw |

| CD33L | 6000-7000 liters | 200-600t/h | 160Kw+200Kw |

| CD40L | 1000-12000 liters | 1000-1400t/h | 160Kwx2+200Kwx2 |

Continuous Intensive Mixers VS Compared to Traditional Mixing Equipment

Compared to traditional mixing equipment, the Co-Nele continuous intensive mixer incorporates advanced engineering concepts and sophisticated control technology. It can handle a wide range of materials with varying properties—from ultra-fine powders to coarse granules, from dry materials to complex formulations requiring the addition of multiple liquids. It seamlessly integrates with upstream and downstream continuous production processes, significantly improving overall production efficiency and reducing unit energy consumption and overall operating costs.

If you're planning a new production line or looking to upgrade an existing mixing process, Co-Nele continuous Intensive mixer is the perfect choice.