Close search

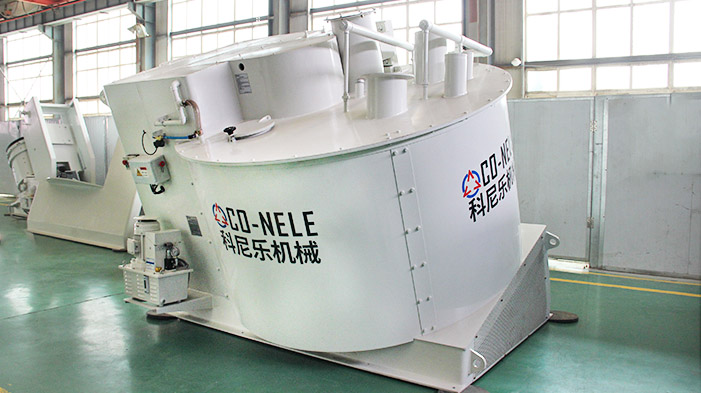

The closed mixing barrel body of the intensive mixing granulator can solve the problem of dust pollution very well. It can carry out granulation test on iron powder and adhesive, and improve the efficiency to meet the needs of customers.

1. Strong granulation: iron powder intermittent granulating machine uses external roller and internal central high-speed rotating rotor at the same time for high speed reverse mixing of powder in the material flow and liquid additives under the dual action of rapid granulation, by adjusting the content of additives and stirring time and stirring frequency can achieve fine tuning of particle size distribution;

2. High granulation rate, high strength: intermittent mixed granulation machine with high granulation rate, dense particles, high strength;

3. Wear resistance and anticorrosion: each wear part of the equipment is installed with wear resistance and anti stick lining board. It can effectively prolong the service life of high-speed motion mechanism and reduce the loss of power;

4. Automatic control: PLC can be used to achieve medium and remote centralized control and full automatic operation, to avoid the error brought by manual operation; Users can automatically complete granulation by pre-setting mixing, adding additive sequence and dosage.

Intensive mixing granulator is mainly used in ceramics, refractory materials, chemical industry, light industry, slag treatment, hazardous waste and municipal waste treatment and other industries that need granulate and mixed materials.

We will contact you within 24 hours.