Bentonite is a material with strong hygroscopicity and high viscosity, renowned for its bonding properties, sealing ability, absorbency, and lubricity. The CONELE bentonite granulator processes bentonite clay into granular form, making it easier to handle and apply.

Bentonite Granules Production Line Solutions:

1.Raw Material Pre-treatment:Screening,crushing,and drying.

2.Batching and Mixing:According to the formula,bentonite and possible additives(such as binders and modifiers)are precisely measured and efficiently mixed.

3.Granulation and Forming:Select the appropriate granulating machine based on product requirements(particle strength,shape,density,etc.).

4. Post-granulation processing: Dryer (for wet processes), cooler, screening machine (for separating qualified granules and returning unqualified materials to the system), coating machine (optional, for anti-caking or slow-release).

5. Packaging and dust removal: The entire production line is equipped with an automated metering and packaging system, dust removal, and environmental protection equipment.

Types of Bentonite Granulators:

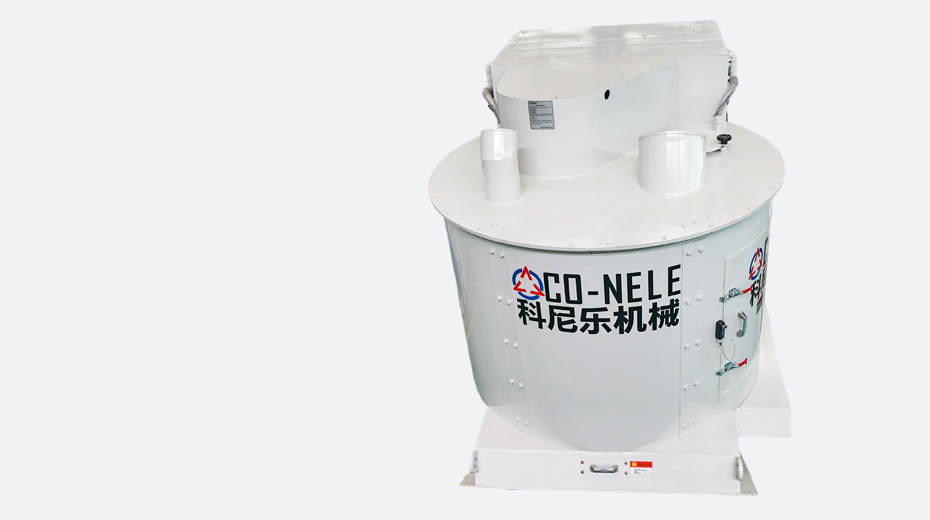

High Mixing Uniformity: Three-dimensional turbulent mixing technology ensures thorough and uniform dispersion of materials.

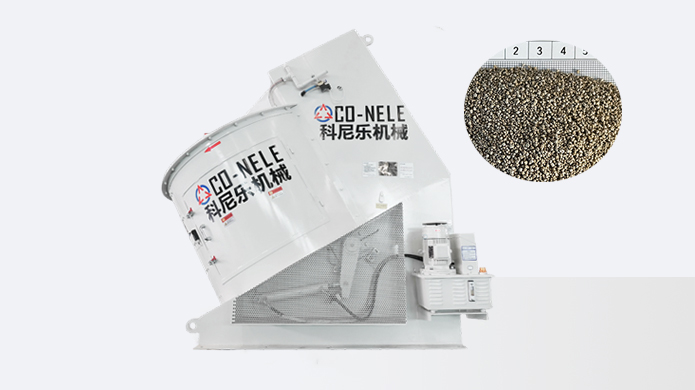

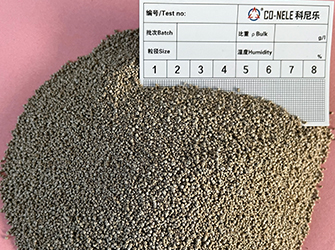

Good Particle Sphericity: Excellent granulation effect, producing rounded and high-strength particles.

Flexible Particle Size Adjustment: The particle size of the finished product can be adjusted within the range of 0.5-10mm according to process requirements.

Durable Equipment: Adopting a wear-resistant design, key components are robust and durable, ensuring a long service life.

Selectable Process Modes: Offers various equipment specifications, supporting continuous or intermittent production to adapt to different production schedules.

Small Bentonite Granulator (CEL01-CR05): Processing capacity: 3kg-75kg per batch, capacity: 18kg-450kg/h, depending on the granulator model.

Large Bentonite Granulator: Capacity range is very wide, reaching 15-40 t/h or even higher depending on the granulator model.

Type Of Granulator Machine

| Type | Out capacity(L) | Out weight(Kg) | Main planet(nr) |

|---|---|---|---|

| CEL5/CR02 | 5 | 6 | 1 |

| CEL10/CR04 | 10 | 12 | 1 |

| CR05 | 25 | 30 | 1 |

| CRO8 | 50 | 60 | 1 |

| CR09 | 100 | 120 | 1 |

| CRV09 | 150 | 180 | 1 |

| CR11 | 250 | 300 | 1 |

| CR15 | 350 | 420 | 1 |

| CRV15 | 500 | 600 | 1 |

| CRV15H | 600 | 720 | 1 |

| CR19 | 750 | 900 | 1 |

| CRV19 | 1000 | 1200 | 1 |

| CR20 | 1250 | 1500 | 1 |

| CR24 | 2000 | 2400 | 1 |