Close search

The main advantages of the integrated equipment for dry mixing and beating are: efficient control of the mechanical energy of the input mixture and its associated shear force; Thoroughly open the agglomerates in the raw material; Uniformly dispersing the adhesive; Directly humidifying active materials, conductive carbon black, and additives to obtain the best results; Online control and adjustment of slurry viscosity; Extremely short preparation time, 30 minutes/batch; Automatic and continuous process monitoring can ensure the optimal quality and consistency of the slurry; Visual interface and data recording of the control system, including temperature, pressure, and input mechanical energy.

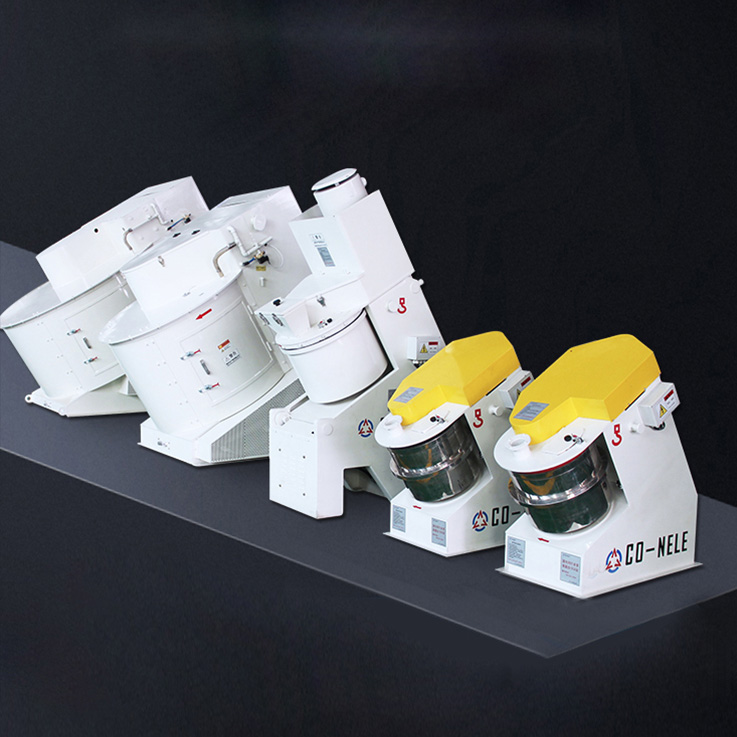

Lithium battery intensive mixer,Mixing ,granulation, coating, dispersion

Today, many devices of co Nele have been used in the fields of all solid-state battery cathode materials, electrolyte preparation, lithium battery precursor and cathode material coating, anode material preparation, lithium battery slurry preparation, and high solid content and pure dry electrodes. In addition, the company can also provide customers in the lithium battery industry with customized solutions for multiple uses.

Mixing and packaging of positive and negative electrode materials for lithium batteries

Integrated equipment for dry mixing and homogenization of lithium battery slurry, high solid content slurry preparation, dry electrode preparation

Mixed preparation of membrane materials

Provide customized solutions for users in the battery industry with multiple functions

We will contact you within 24 hours.