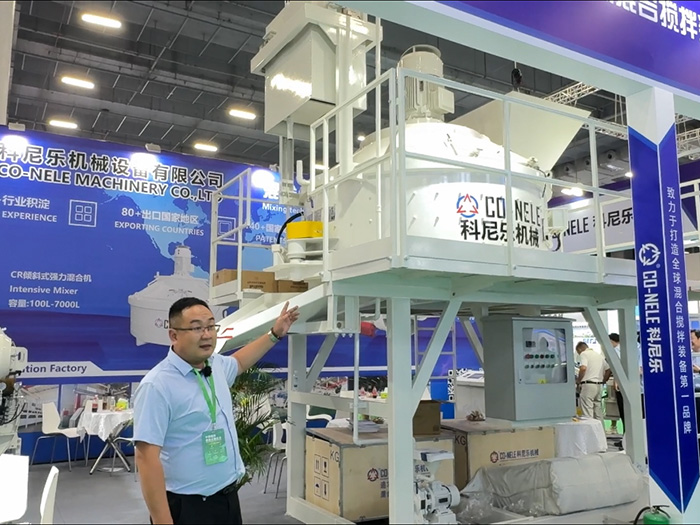

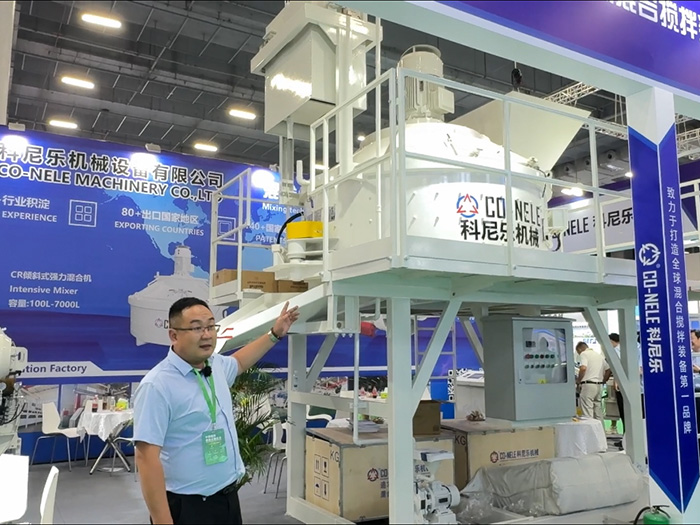

The three-day 2025 China International Concrete Expo concluded successfully on September 7th at the Guangzhou Canton Fair Complex. This expo brought together leading companies and innovative achievements from the global concrete industry, providing a central platform for insights into industry trends. At this highly anticipated industry event, Qingdao CO-NELE Machinery Equipment Co., Ltd., with its flagship exhibits—the CR09 Intensive Mixer and its UHPC (Ultra-High Performance Concrete) modular plant solutions—stole the spotlight, showcasing the technological strength and innovative vitality of Chinese manufacturing in the high-end mixing and mixing sector.

The CR09 Intensive Mixer and UHPC Modular Station, showcased by Coneline Machinery at the 2025 China International Concrete Expo, are key examples of Coneline Machinery's leading technology.

Feature Dimension

| CR09 Intensive Mixer

| UHPC mobile module station

|

Design and Construction

| Tilted cylindrical design, typically constructed of wear-resistant materials

| Modular design enables rapid relocation and deployment; compact structure saves space; typically offers foundation-free installation

|

Mixing and Stirring Performance

| Counterflow principle and strong shearing achieve high-speed, uniform mixing with zero dead spots.

| Equipped with a high-efficiency mixing unit (such as a vertical planetary concrete mixer), ensuring highly uniform dispersion of UHPC materials.

|

Intelligence and Control

| Advanced control technology allows for flexible parameter adjustment, intelligent automated production, and strong process controllability.

| High-precision automated control system enables automatic weighing of multiple components and automatic control of process parameters, resulting in a high degree of automation.

|

Production Efficiency and Cost

| Short mixing time, relatively low energy consumption, and multi-functionality (mixing, dispersing, granulation, heating, vacuuming, and cooling) are all integrated.

| High production efficiency, rapid deployment, shortened construction time, and significantly reduced labor costs.

|

Adaptability and Reliability

| Adapts to materials of varying formulations, particle sizes, and moisture contents, delivering high uniformity and consistency, and has a wide range of applications.

| Strong environmental adaptability and adaptability to complex working conditions; equipped with an automatic cleaning module for easy maintenance and upgrades.

|

With their powerful mixing capabilities and wide material compatibility, the CR09 Intensive Mixers play a key role in many fields requiring extremely high mixing uniformity:

New Materials: They are used in the production of high-performance building materials such as UHPC (ultra-high performance concrete), ECC (extremely ductile cementitious composites), and FRC (fiber-reinforced concrete), effectively addressing fiber dispersion challenges.

Refractory: They improve the uniformity of raw material mixing in refractory products, thereby ensuring stable physical properties.

Metallurgy: They are used for uniform mixing of metal powders and other materials, laying the foundation for subsequent forming and sintering processes.

Other Industries: They can also be used in industries such as ceramics, glass, and new energy battery materials.

Application Scenarios for UHPC Mobile Module PlantsThe flexibility and high productivity of UHPC Mobile Module Plants make them particularly popular in the following scenarios:

Fast-track construction projects: For projects requiring frequent site changes, such as the phased construction of bridges, tunnels, and water conservancy projects.

Space-constrained construction sites: Especially for high-density urban construction projects or projects with limited space.

Precast component plants with high demand for UHPC materials: They can serve as the main production equipment, providing stable, high-quality ultra-high-performance concrete.

About Co-nele Machinery Co., Ltd.:Qingdao Co-nele Machinery Co., Ltd. is a national high-tech enterprise specializing in the research and development and production of high-end mixing equipment. The product line covers multiple series including high-power mixers, twin-shaft mixers, planetary mixers, etc., which are widely used in multiple industries such as concrete, refractory materials, ceramics, glass, etc. The products are exported to dozens of countries and regions around the world, and have won wide acclaim in the market for their excellent performance and stable quality.