Close search

These problems are very common in refractory material production:

✓ Uneven mixing: Dead zones exist in the mixing of refractory mortar and castables, leading to cracking and insufficient strength in fired refractory bricks;

✓ Low efficiency: Traditional mixers have long mixing times, failing to meet delivery deadlines;

✓ High maintenance costs: Mixing arms and liners wear out quickly, requiring monthly replacements, and downtime for maintenance disrupts production.

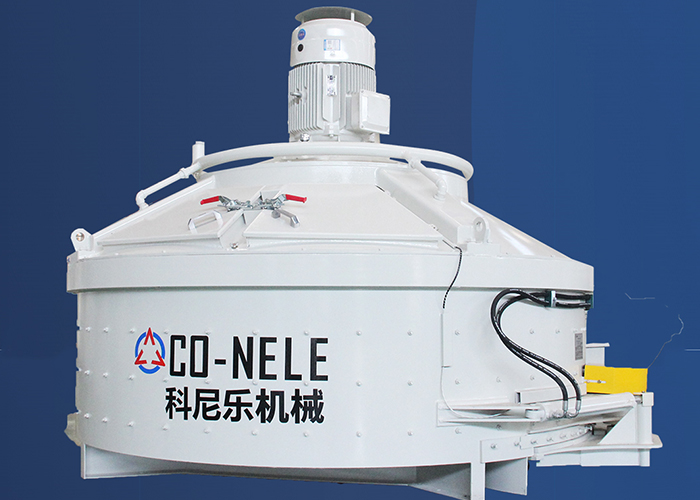

Stop struggling! CONELE refractory planetary mixer precisely solve these problems!

Pain Point 1: Uneven mixing → High scrap rate?

CONELE vertical shaft planetary mixer: Revolution + rotation mixing mode, high uniformity!

Unlike traditional single-shaft mixers that "incompletely scrape the walls," CONELE's vertical shaft planetary structure allows the mixing paddles to revolve around the shaft while simultaneously rotating at high speed. Whether it's high-viscosity refractory mortar, large-particle castables, or lightweight insulation materials, it can mix them evenly and thoroughly.

Pain Point 2: Low Efficiency → Missing Delivery Dates?

CONELE refractory planetary Mixer: Accelerated Production! Reduced Time, Doubled Capacity! Addressing the "high specific gravity, difficult dispersion" characteristics of refractory materials, Koneler optimizes the mixing trajectory, combined with a high-speed rotor, for more efficient breaking up of lumps.

Pain Point 3: Cost of Wear Parts + Downtime Losses?

CONELE Vertical Shaft Planetary Mixer: Doubled Wear Part Life, Reduced Maintenance Costs! The mixing arms and liners are made of highly wear-resistant materials; and the upgraded sealing design reduces wear on core components.

We will contact you within 24 hours.