Close search

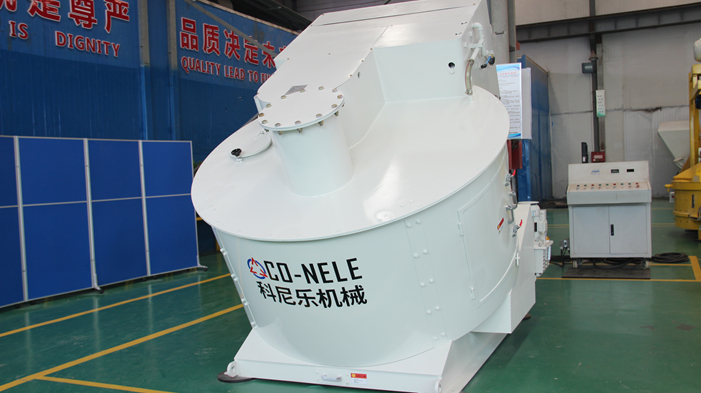

Detailed explanation of the mixing process of the intensive mixer:

1. Forced stirring type mixing is realized by the rotation of the blades: the intensive mixer uses multiple stirring blades (which can be replaced individually) to rotate, and forcibly stir the inside of the material in multiple directions and angles. Homogeneous and efficient. At the same time, the scraper blade continuously strips the materials left at the bottom and edge of the tank and pushes them to participate in the mixing movement.

2. The mixing barrel of the intensive mixer rotates to achieve gravity-diffusion mixing: the mixing barrel rotates rapidly, raising the center of the material continuously, promoting the macro-mixing in the upper and lower directions, and maintaining the force-diffusion mixing to achieve the purpose of uniformity.

We will contact you within 24 hours.