Close search

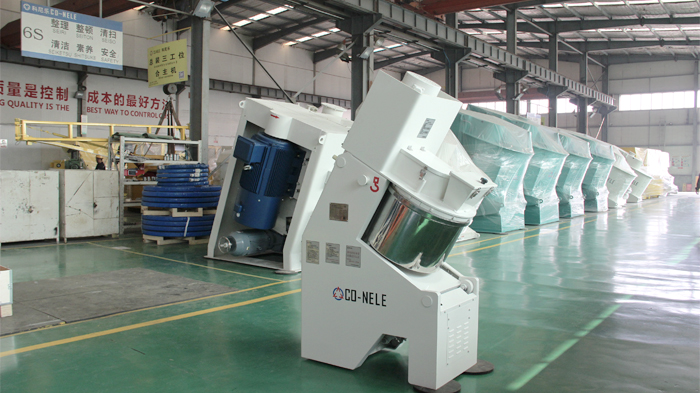

Intensive Shear Mixer for Mixing UHPC at Site and at Laboratory

The intensive shear mixer has better advantages in mixing UHPC. The material is fed into the intensive shear mixer, and the rotating drum takes the material to turn over. After the material reaches the top, it is thrown down under the action of inertia, and the material is sheared in mid-air. Cutting action, continuous diffusion movement, forming a mixing process of diffusion mixing, shear mixing cooperation.

The intensive shearing mixer pushes the material directly to the scraper arm, and is driven by the high-speed rotation of the scraper arm to form an efficient circulation type effect.

The materials form a three-dimensional space structure under the action of mechanical force and its own gravity, which promotes the mixing of the materials up and down.

Compared with standard mixing equipment, the intensive shear mixer has higher production efficiency, better mixing effect and shorter mixing time.

We will contact you within 24 hours.