Close search

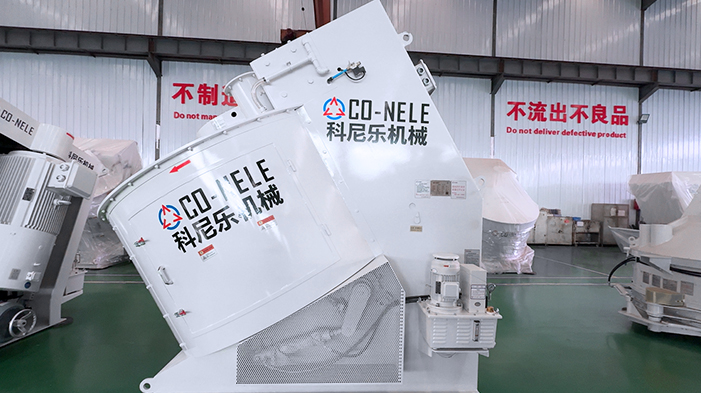

A welding material intensive mixer is a specialized equipment used to mix flux, powders, and other materials used in welding processes. This intensive mixer is designed to ensure a uniform mix, which is crucial for the performance and quality of welding materials. Here is an overview of welding material intensive mixer:

Main Features:

- High-shear mixing: The intensive mixer is equipped with high-performance mixing blades to ensure even mixing of materials.

- Temperature control: Including temperature regulation for the mixing process, which is important for materials that are sensitive to heat.

- Vacuum capability: Can operate in a vacuum environment to remove air and prevent the formation of bubbles, which is crucial for certain welding applications.

- Automatic control: Equipped with an automatic control system for precise feeding and consistent mixing results.

Applications:

-Flux Mixing: Ensures that flux is mixed evenly, improving its flow and coverage during welding processes.

-Powder Metal Mixing: Used for producing metal powders for 3D printing and other processes.

-Ceramic Material Processing: Used for producing ceramic powders and slurries for various applications.

-Other Industrial Materials: Suitable for mixing other industrial materials with high requirements for uniformity.

Advantages:

-Improved product quality: even mixing leads to better welding results.

-Increased efficiency: the high-speed mixing action reduces the time needed for achieving even mixing.

-Cost savings: The intensive mixer can help reduce waste and rework by ensuring consistent mixing.

We will contact you within 24 hours.