Close search

Planetary concrete mixers provide a reliable solution for high uniformity and operability.

Vertical axis planetary mixers provide a reliable solution for producing concrete mixtures with high uniformity and operability. Our vertical axis planetary concrete mixers use planetary mixing blades to mix all types of concrete such as precast concrete, fiber-reinforced concrete, self-compacting concrete and other aggregates.

Mixer function:

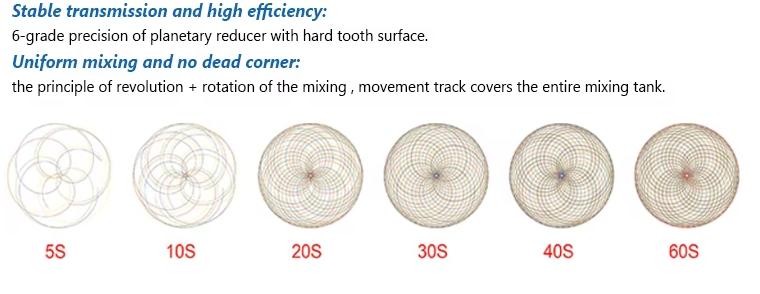

* High mixing efficiency, high uniformity;

* Self-developed reducer, high strength, reliable performance;

* Easy maintenance;

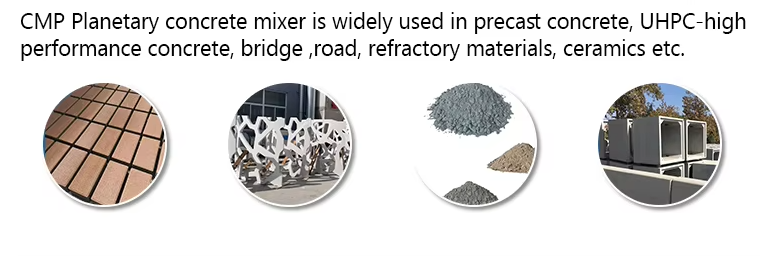

* Flexible layout, 1-3 discharge doors can be selected for different production lines;

* Short mixing time;

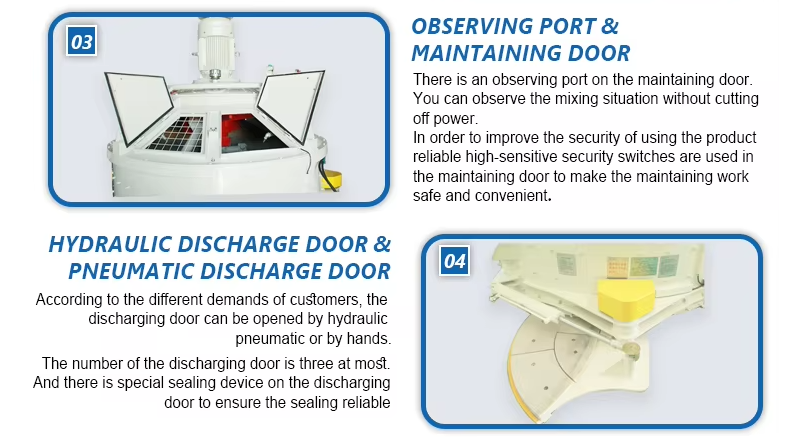

* High safety, open the access door main engine power off;

* Interchangeable wear-resistant liner with fixed bolts;

Mixer components:

The mixer is designed to provide better mixing performance. Each component is carefully crafted and assembled to provide long-lasting material mixing production capabilities.

- Drive device

The driving device is composed of well-known brand motors and self-developed special transmission. Transmission gear adopts hard helical gear with high reliability and long service life. Gearbox noise is low, factory indoor installation is also the preferred product.

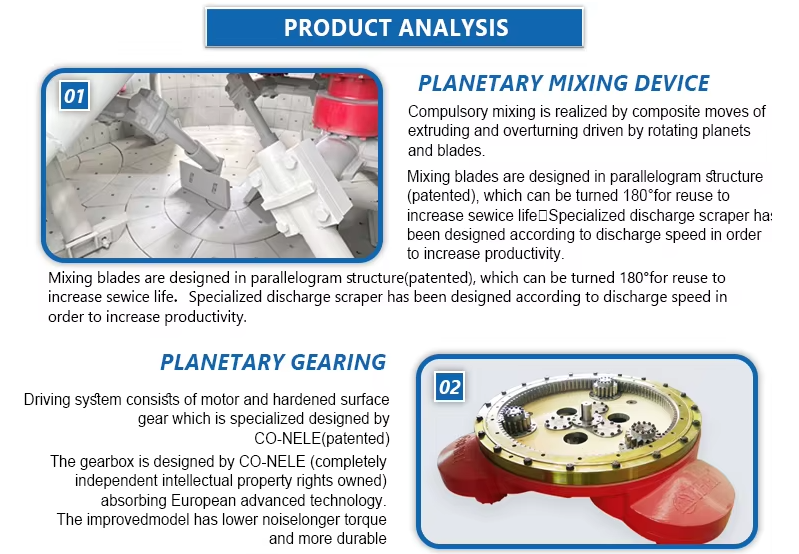

- Mixing tools

Mixing tools include blades, mixing arms, bottom scrapers, side scrapers, and quick mixing tools (optional). In the mixing process, the material realizes the three-dimensional mandatory mixing by squeezing, shearing, flipping and other composite actions. The scraper prevents the material from sticking to the inner lining of the mixer. Different speeds and mixing tool structures can be selected according to customer requirements.

- Materials

Replaceable lining is installed in the cylinder body, you can choose according to your raw material characteristics: high chromium alloy, polymer PE, wear-resistant steel, ceramic, stainless steel, etc.

- Discharge device

According to different requirements of customers, the discharge door can be opened and closed by pneumatic or hydraulic means. The hydraulic discharge method has stable pressure, which can realize the complete or partial opening of the discharge door and open the discharge door through the manual discharge function of the pump station when there is a power failure to avoid material agglomeration. Optional hydraulic pump station with double discharge doors.

- Access door

The large access door is convenient for maintenance personnel to replace internal worn parts. The air spring is installed on the access door, which is light and convenient to open and close! The inspection door is provided with an observation port, which can observe the material condition when the mixer is working normally under the state of constant power.

We will contact you within 24 hours.