Close search

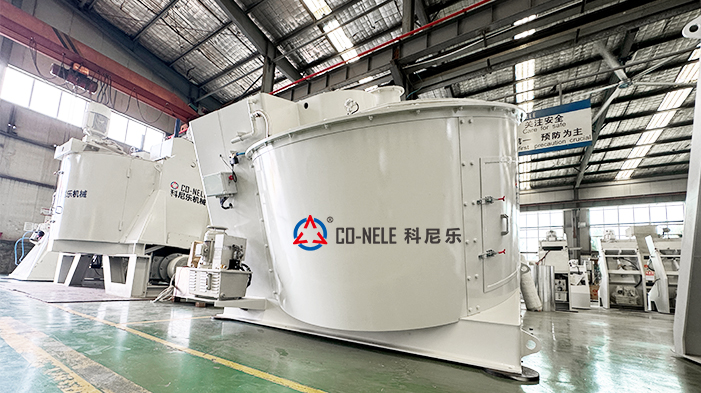

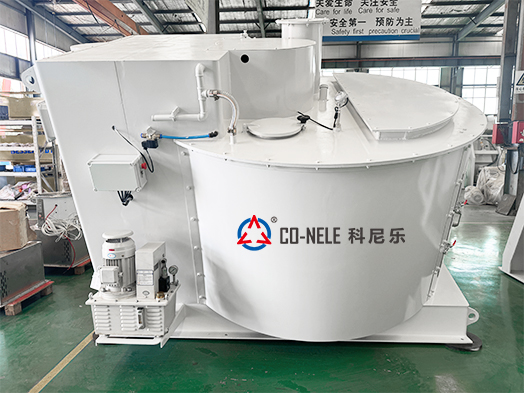

An intensive granulating mixer is a specialized piece of equipment designed to efficiently mix and granulate abrasive materials and ceramics. This type of mixer is particularly useful in industries that require precise control over the particle size and homogeneity of the final product, such as in the manufacturing of ceramics, abrasives, and other advanced materials.

Key features and benefits of an intensive granulating mixer include:

1. High Shear Mixing: The mixer uses high shear forces to ensure thorough mixing of the materials. This helps in achieving a uniform distribution of particles, which is crucial for the performance of abrasive materials and ceramics.

2. Granulation Capabilities: The mixer can also perform granulation, which involves forming small, spherical particles from the mixed materials. Granulation is important for improving the flow properties of powders and ensuring consistent quality in the final product.

3. Customizable Settings: Intensive granulating mixers often come with adjustable settings for speed, mixing time, and moisture content. This allows operators to optimize the mixing and granulation process for different materials and applications.

4. Dust Control: Many mixers are equipped with dust control systems to minimize airborne particles during the mixing process. This is particularly important when working with fine powders, which can be hazardous if inhaled.

5. Easy Maintenance and Cleaning: The design of these mixers typically allows for easy access to internal components, making maintenance and cleaning straightforward. This helps in reducing downtime and ensuring consistent performance.

6. Versatility: These mixers can handle a wide range of materials, including various types of ceramics, abrasives, and composite materials. They are suitable for both batch and continuous processing.

In summary, an intensive granulating mixer is a versatile and efficient tool for mixing and granulating abrasive materials and ceramics. It offers precise control over the mixing process, resulting in high-quality, uniform products suitable for various industrial applications.

We will contact you within 24 hours.