Close search

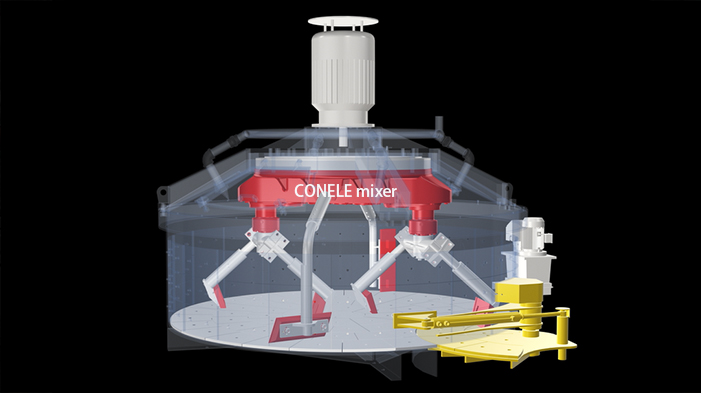

Planetary concrete mixers are suitable for mixing materials in most industries, especially for materials with added fibers and high viscosity, such as ultra-high performance concrete, glass raw materials, refractory materials, metallurgy, ceramic materials, etc. The mixer has a large internal space and a streamlined mixing arm to reduce mixing resistance and ensure smooth mixing.

The parallelogram mixing blades of the planetary concrete mixer can be flipped and reused, and the uniformity of material mixing can be improved by flipping and squeezing the materials. For vulnerable parts such as blades and liners that are in direct contact with the materials, materials with high wear resistance will be selected.

Long-life and high-quality mixing equipment are the key considerations for mixing effect and cost-effectiveness. Planetary concrete mixers have demonstrated advantages such as high efficiency, high uniformity, high environmental protection, and flexible layout.

Even mixing - high homogeneity: the revolution and rotation of the mixing blades, the movement trajectory quickly covers the mixing barrel

Smooth transmission - high efficiency: 6-level hardened gear reducer and oil bath design, can run stably for a long time without overheating, low noise, high torque, strong durability

Good sealing - high environmental protection: there is no leakage problem, ensuring the sealing of the mixing process

Can be used in a variety of occasions - flexible layout: 1-3 discharge doors can be flexibly selected, and the size specifications can be customized to meet the needs of different production lines.

We will contact you within 24 hours.