Close search

Polymer-modified concrete has special requirements compared to “ordinary” concrete mixes:

*Homogeneity / dispersion is more critical. Polymers need to be uniformly distributed (emulsion, latex, powder, etc.).

*Low to medium slump, often stickier mixes, risk of sling-off or sticking to parts.

*Wear and abrasion resistance matters more because the polymer additives can be aggressive, or the aggregates can be finer or more abrasive.

*Power and mixing dynamics need to deliver enough shear to disperse polymer, but not damage polymer components through over-shear (depending on the polymer type).

*Clean-up & maintenance is more burdensome due to stickiness; discharge gates, scraper arms, pan walls, etc., need to avoid build-up, easy clean-out.

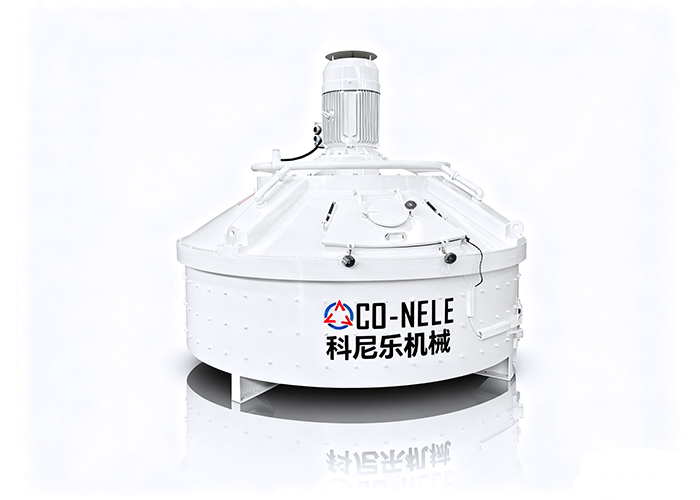

Planetary concrete mixers are often well suited, because their mixing motions (star arms, revolutions + rotations, scrapers) help with high uniformity, fast mixing, and reach all parts of the mixing pan (less dead zones). They are used for special concretes, UHPC, dry, semi-dry, fiber-reinforced, etc.

Mixing arms / stars rotation + revolution Ensures turbulent shearing and good dispersion of polymer and fine particles.

Strong scrapers Keep material from sticking on walls / bottom; polymers tend to increase stickiness.

Wear-resistant liners/blades (Ni-Hard, HARDOX, high chromium alloys, etc.) To resist abrasion from aggregates and added wear due to polymer matrix.

High power motor and robust gearbox To provide torque under dense or stiff mixes; avoid overheating or stalling.

Flexible discharge: multiple doors, full sweep For ease of discharge and cleaning; residual polymer mix can stick if not fully cleared.

Control of mixing time, speed Polymer mixes may need longer/more controlled mixing vs high-slump mixes. Being able to slow/fine control is helpful.

Capacity matched to project scale Small mixes may be easier to manage; large mixers must maintain uniformity.

We will contact you within 24 hours.