The CONELE metal powder granulating mixer, through integrating the mixing and granulating processes, demonstrates outstanding performance in multiple fields such as powder metallurgy, new energy, and ceramics. Specifically, it shows remarkable advantages in improving the processing efficiency of metal powders and the quality of finished products.Technical Advantages and Core Characteristics of Metal Powder Granulating MixerThe CONELE metal powder mixing and granulating machine encompasses several core technical advantages:1. Exceptional Mixing Homogeneity: The equipment operates based on the principle of three - dimensional turbulent mixing. This principle enables it to achieve molecular - level dispersion, resulting in an extremely high degree of mixing homogeneity. As a result, it effectively addresses the common problems of caking and delamination in traditional processes.2. Superior Granulation Quality: The granules formed after granulation exhibit high density and excellent sphericity. The spheroidization rate of the granules is significantly better than that of traditional equipment, providing a solid foundation for subsequent processing steps.3. Efficient Integrated Workflow: By integrating the two separate processes of mixing and granulating within a single machine, it substantially reduces the production cycle. This integration not only enhances production efficiency but also decreases energy consumption and labor costs.4. Flexible On - line Dynamic Granule - size Adjustment Technology: During the production process, operators can exercise real - time control and adjustment of the granule size. Parameter adjustment can be accomplished without halting the machine, thus enhancing the flexibility and continuity of production.5. Diverse Model Selection: The machine is available in a comprehensive range of models. It covers from small - scale 1 - liter laboratory models to large - scale 7000 - liter models for industrial production lines, meeting the requirements of different stages, from R & D trials to large - scale production.6. Convenient Discharging and Cleaning: With the adoption of either tilting discharge or bottom double - discharge modes, the hopper can be rapidly emptied within a short period. Moreover, the cleaning process is convenient, effectively preventing cross - contamination between different batches of materials.7. Intelligent Control and Robust Design: The machine can be connected to a PLC control system, enabling fully automated operation and the storage and retrieval of process parameters. In addition, considering the wear issues in different industries, the cylinder provides multiple wear - resistant lining options, ensuring high durability of the equipment.

Tags:

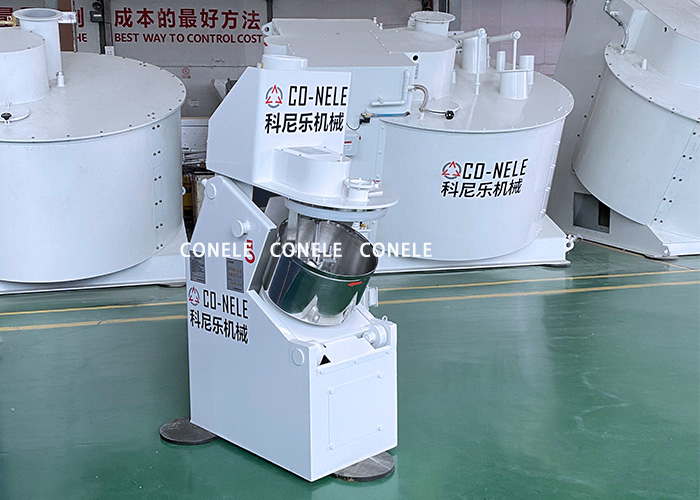

CR Metal Powder Granulating Mixer

Mixing and Granulating Machine

intensive mixer

Back To The List