Close search

In the magnetic materials industry, tilting mixed granulators play a key role in improving production efficiency, optimizing product quality and simplifying process flow.

The main advantages and applications of inclined mixing granulator in the magnetic material industry:

1. Improve mixing uniformity

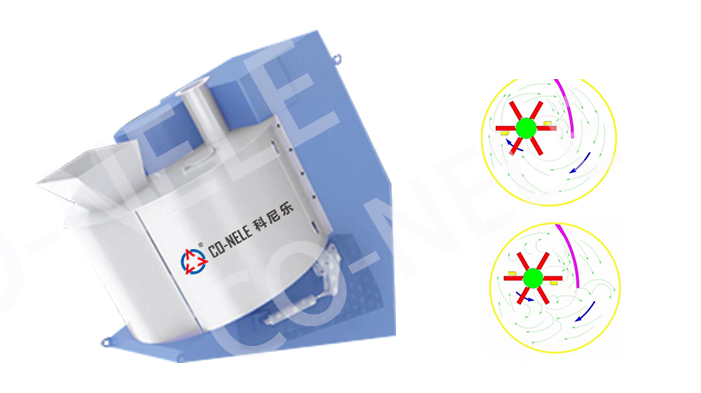

- Tilting mixing granulator adopts a unique tilting structure design, combined with high-speed rotating three-dimensional mixing tools, so that the material can fully flow and disperse during the mixing process. This design significantly improves the mixing uniformity, ensures the uniformity of the distribution of each component in the magnetic material, and lays a good foundation for the subsequent molding.

2. Optimize the granulation effect

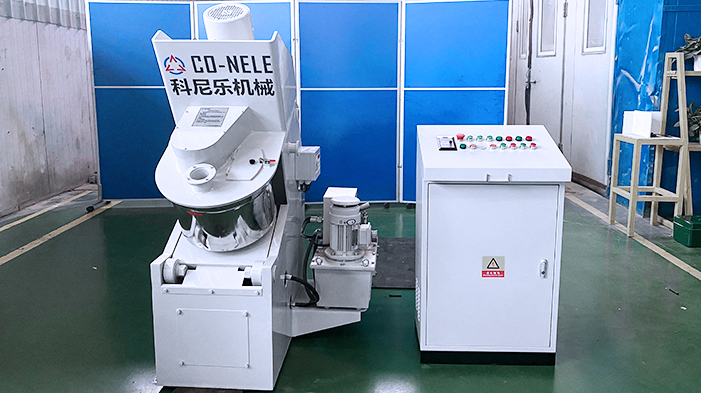

- Granulation is a key step in the preparation of magnetic materials. The inclined mixing granulator not only has an efficient mixing capacity, but also can realize the granulation of the material through the pelletizing disk while mixing. This integrated process simplifies production steps, increases production efficiency, and provides better control over particle size, shape, and distribution.

3. Improve production efficiency

- Intensive granulating mixer has efficient and continuous production capacity, which can meet the high production efficiency requirements of magnetic material preparation process. At the same time, the equipment can also adapt to the production needs of different scales, from small batch preparation at the laboratory level to large-scale production at the industrial level.

We will contact you within 24 hours.