Close search

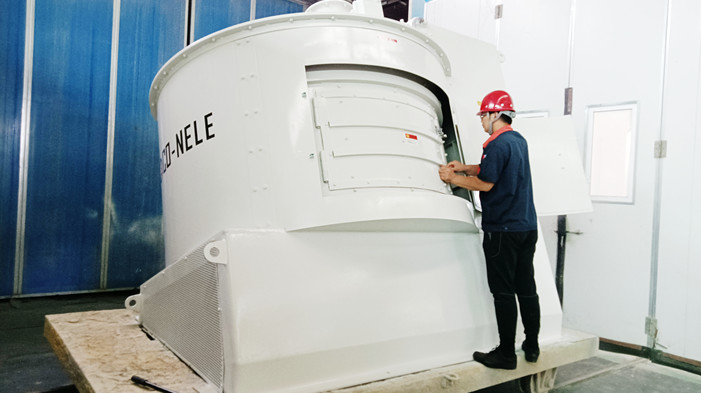

Intensive Mixer CQM750 for CONELE

Under the combined action of high-speed rotor, stirring plate and multi-functional scraper, the intensive mixer can make the material achieve the best mixing uniformity in the shortest time.

1. After the material reaches the mixing range of the high-speed rotor at the eccentric position, the high-intensity mixing is completed, thereby forming a high-precision mixing of the material.

2. During the rotation process, the specific inclination angle of the intensive mixer is convenient to send the material to the top. When the material reaches a certain height, it falls under the action of gravity.

3. When the intensive mixer is mixing materials, the rotating speed of the drum and the high-speed rotor can be reduced according to the process requirements. It is also possible to adjust the speed during the mixing process to complete the staggered mixing process.

4. The multi-functional scraper of the intensive mixer disturbs the flow of the material during the mixing process, transports the material to the mixing range of the high-speed rotor, and at the same time prevents the material from sticking to the periphery and bottom of the cylinder, ensuring that the material fully participates in the mixing.

5. The mixing disc and high-speed rotor of the intensive mixer rotate in different directions, so that the materials are vigorously mixed in the strong Intensive mixer. In order to meet the special process requirements of some materials, the stirring plate and the high-speed rotor can also be set to rotate in the same direction.

We will contact you within 24 hours.