Laboratory 1L Heating Micro Lithium Battery Cathode Material Mixer

Preparation of positive and negative electrode slurry: used to mix positive electrode materials, negative electrode materials, conductive agents, binders and solvents to form a uniform and stable slurry to ensure the conductivity and consistency of the electrode.

Processing of high solid content slurry of silicon-carbon negative electrode: specially designed stirring paddles can handle viscous materials with a solid content of more than 50%, reduce the amount of solvent, and improve production efficiency and slurry quality.

Pre-research of solid-state batteries: oxygen-free stirring in a vacuum environment, adapted to the development of the next generation of solid electrolyte materials, and meet the special process requirements in the production process of solid-state batteries.

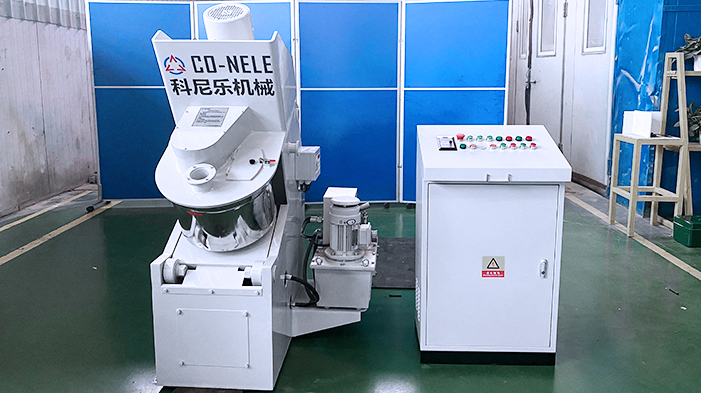

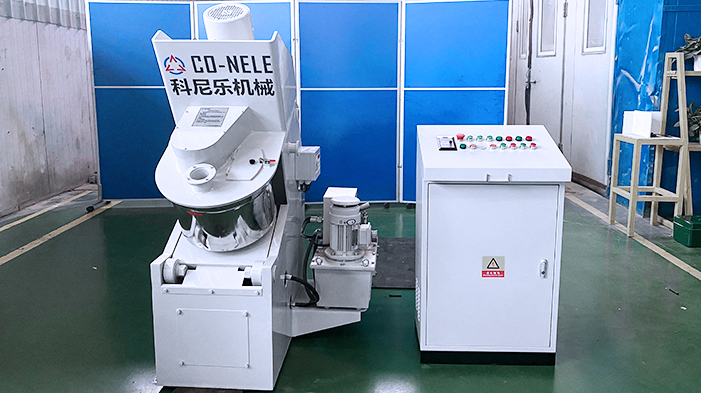

CEL01 Intensive Laboratory Lithium battery mixer

CEL01 Intensive Laboratory Lithium battery mixer for Mixing and granulation of industrial raw materials.

Flexible high-performance multifunctional mixer for R&D and small-scale production.

For example,used for mixing,granulating,coating,kneading,dispersing,dissolving,fiber separation,etc.

Volume:1L

Mixing Power:400W

Adjustable tilt angle 0°,10°,20°and 30°

The mixing cylinder is configured according to user needs,the internal rotor and side hanging plate are available in a variety of optional materials,the internal lining can be customized,and various wear protections are provided according to requirements.

Laboratory 1L small mixer functions optional:vacuum,heating,cooling functions.

CEL01 Intensive Laboratory Lithium battery mixer Advanced Control Technology

The control system is advanced and flexible,with an optional touch screen,intuitive operation,and infinitely adjustable tool speed in the direction of rotation.Users can set and adjust the rotation speed(mixing disk),power(mixing tool),temperature,time,etc.through a graphical interface.

Structural composition : There is a rotating mixing disk, and the inclined rotating mixing disk is connected to a dual-acting wall scraper.Working principle : The rotating mixing disk carries the material for centrifugal motion to produce high-speed differential flow. The wall scraper ensures the vertical circulation of the material to prevent the material from sticking to the wall and bottom of the disk, and accelerates the unloading at the end of the mixing cycle.Feature : It can complete multiple functions such as mixing, precise dispersion, mixing, granulation, surface treatment, and surface coating of raw materials. It can effectively overcome the unevenness of lithium battery materials caused by different characteristics such as particle size, density, shape, and viscosity. It has strong adaptability to materials, high universality of mixing uniformity, and good material homogeneity.

Lithium-ion battery:Positive electrode materials: Common ones are lithium cobalt oxide (LiCoO2), lithium manganese oxide (LiMn2O4), nickel cobalt manganese oxide (Li(NixMnyCoz)O2, that is, ternary materials), lithium iron phosphate (LiFePO4), etc. These materials are responsible for the embedding and de-embedding of lithium ions during battery charging and discharging.Negative electrode materials: mainly graphite materials, such as natural graphite and artificial graphite, in addition to silicon-based negative electrode materials, etc., used to store and release lithium ions.Electrolyte: Usually an organic solution of lithium hexafluorophosphate (LiPF6), which conducts lithium ions between the positive and negative electrodes and plays a role in charge transfer.Diaphragm: Generally made of polymer materials such as polyolefins (such as polyethylene, polypropylene), its function is to isolate the positive and negative electrodes, prevent short circuits, and allow lithium ions to pass through.Current collector: The positive electrode current collector generally uses aluminum foil, and the negative electrode current collector generally uses copper foil, which is used to collect and conduct current.